Productive forces

Aug 05,2025 | CANMEILIGHTS

· Productivity synergy - 12 professional production linesProductivity skeleton ——37 precision instruments

Equipped with 37 pieces of precision equipment covering all production links, the company ensures stable accuracy and efficiency in production. These include integrating spheres, spectrum analyzers, and other light efficiency testing equipment. These instruments quantitatively monitor core parameters such as luminous flux, color temperature, color rendering index, and flicker with laboratory-level precision. Using a testing system calibrated with proprietary algorithms, the company strictly controls the deviation of each value within ±1.5%, ensuring that the color difference of lamps for the same project remains at a professional level of ≤3 SDCM.

From the ground up, the technology achieves flicker-free operation, maintaining UGR (Uniform Glare Ratio) within visual health thresholds, ensuring that every beam of light meets the stringent standards of "precise light control and comfortable eye protection."

Integrated with environmental monitoring equipment such as salt spray chambers and constant temperature and humidity chambers, this comprehensive testing system simulates complex environments such as high temperature and humidity, coastal salt spray, and extreme temperature swings, ensuring product performance stability in diverse regions and environments. Experience product quality that lasts as long as new and remains stable.

· Productivity engine – 16 professional R&D personnel

The depth of expertise within the R&D team is the core foundation of technological innovation. Canmeijia has assembled a multidisciplinary R&D team spanning mechanical engineering, materials science, and automated control. Eight members hold a master's degree or higher, and over half have over 10 years of experience in the precision manufacturing industry. This highly experienced and experienced R&D team provides a solid foundation for technological development.

From the initial product design to the selection of core materials and quality control during production and processing, every step is overseen by dedicated professionals. Leveraging their expertise, they control product precision and performance thresholds, ensuring a high yield rate.

Since its founding in 2012, the Canmeijia team has developed over a thousand products, obtained over 20 patents, and registered national invention patents, as well as numerous utility model and design patents. These efforts effectively address practical application issues, enhance product functionality and practicality, and create recognizable products, earning them national high-tech enterprise certification.

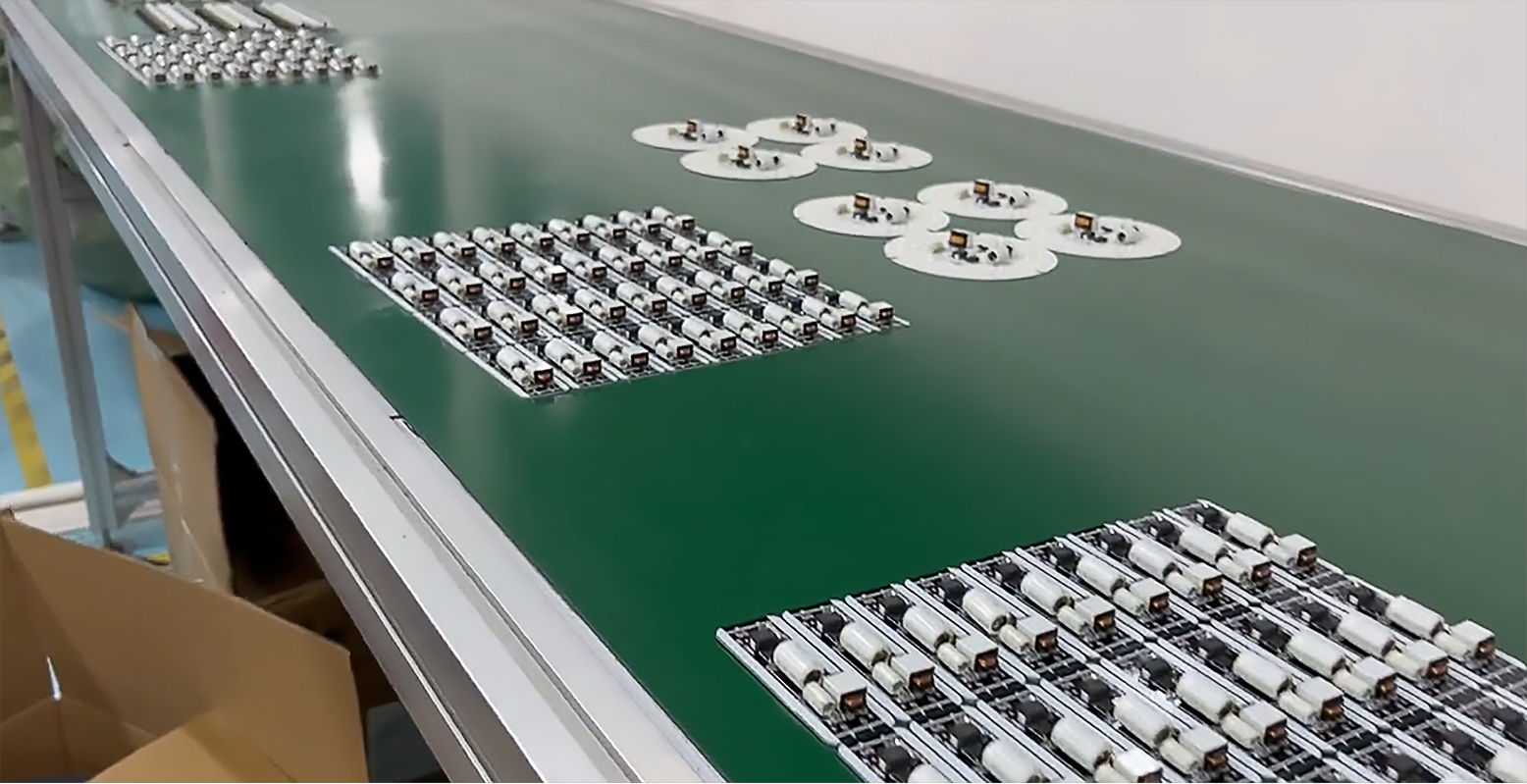

· Productivity synergy - 12 professional production lines

With over 300 employees and 12 production lines operating at full capacity, the company produces over 1,000 products daily, a figure that continues to increase annually. Following the intelligent transformation of its production lines in 2024, production efficiency per line will increase by 15%, providing a guaranteed production capacity to meet the growing demand driven by future market expansion. Currently, Canmeijia sells 245 products with a total inventory exceeding 100,000 units. The company plans to add 107 products to its shelves by 2026, covering lighting fixtures in various categories.

These 12 specialized production lines cover core processes, vertically integrating every production step and maintaining tight control over every aspect of the production process. This results in an 18% higher yield rate than a decentralized OEM model. This also reduces intermediate procurement processes, reducing quality redundancy costs by approximately 15%, making Canmeijia's products more competitively priced.

· Sustainable productivity guarantee - special quality control

Quality control capabilities run through the entire production process and are the guarantee for sustainable development of productivity. In the material selection process, we have established a dual guarantee of "high-quality suppliers + comprehensive testing system", cooperating with many high-quality suppliers to lock in source quality and control the defect rate at an extremely low level;

In addition, we strictly follow the ISO9001 quality management system standards and have 10 professional QA/QC inspectors to ensure continuous improvement of product quality and production processes. All products have passed international certifications, including FCC, CE, RoHS, BIS, CCC, etc., to provide customers with high-standard products.-.png?w=1637&h=786)

Before leaving the factory, each product must pass tests including salt spray, drop, and extreme environment tests. The purpose is to focus on the geographical environment of different sales regions at home and abroad, fully unleash the various performance of the products, and ensure that products with outdoor attributes can still maintain a luminous flux of 98% under extreme environments. At the same time, electrical safety is enhanced and the frequency of damage and replacement is reduced.

For the detection of basic properties such as light efficiency, quality, and visual health, high-precision integrating spheres and spectrum analysis systems are used for strict measurement;

Initial Luminous Flux: ≥ 95% of the nominal value, ensuring the product achieves the expected brightness.

Luminous Efficacy (lm/W): ≥ the nominal value and meets the target market's energy efficiency labeling requirements.

Color Temperature Consistency: Color temperature deviation within the same batch of products is strictly controlled within ±100K (for standard white light products), ensuring uniform light color.

Color Rendering Index: Ra ≥ 80, faithfully reproducing the colors of objects.

Lumen Maintenance: Under rated operating conditions, the lumen maintenance must be ≥ 90% or ≥ 98%, verifying the long-term stability of the product's light output.

This ensures stable and efficient light output throughout the product's lifecycle!

With unified production lines, cluster equipment, and a professional R&D team, CANMEIJIA has made continuous breakthroughs in production:

▶Production efficiency improved: 12 production lines seamlessly connect, producing over 1,000 lamps daily.

▶Root cause analysis accelerated by 60%: 37 pieces of equipment are interconnected, enabling precise identification of the source of problems and timely adjustments.

▶Annual pass rate increases for three consecutive years: from 95% first-time pass rate in 2021 to 98.5% in 2024.